With the Original Beet Juice Tire Ballast, you’ll maximize pulling power and reduce the risk of tipping — all while protecting your rims from corrosion

Tractor-owners, especially those with subcompact models, know the value of added ballast, particularly liquid tire ballast. Rim Guard’s innovative product offers a plethora of benefits to any heavy equipment operator in need of tire ballast, all the while negating any possible effects of corrosion. Whether an ag-producer, construction operator, forester, utilities worker, or a homeowner with a compact or subcompact tractor for snow removal, Rim Guard’s Original Beet Juice Tire Ballast isn’t what your grandpa used, but he probably would’ve if he could’ve.

Beet Juice Tire Ballast is tough to beat

Any operator who’s ever slipped about the slop with a tractor’s wheels spinning knows the importance of having some weight in those tires. And whereas weight-plates loaded on the front or rear can offer too much weight too high, liquid tire ballast takes the weight directly to the lowest point and maintains that center of gravity while in motion.

Beet Juice Tire Ballast is an American-made product that is formulated using a byproduct of the sugar beet manufacturing process, which offers the heaviest non-corrosive liquid ballast on the market today. Non-toxic, biodegradable, and water soluble, producers don’t have to worry if they spill the material around livestock or plants. Freeze-resistant to -35 degrees Fahrenheit, the product is effective with or without tubes.

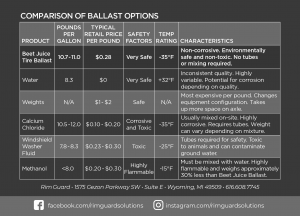

And the numbers really do tell the tale. At 10.7-11.0 pounds per gallon, Beet Juice Tire Ballast’s closest rival is calcium chloride at 10.5-12.0. Meanwhile, water weighs in at 8.3 pounds per gallon, with windshield water fluid at 7.8-8.3, and methanol under 8 pounds per gallon. In terms of cost, Beet Juice Tire Ballast retails at about $0.28 per pound, with calcium chloride coming in between $0.10-$.20, windshield washer fluid at $0.23-$0.30, and methanol at $0.20-$0.30. But keep in mind the substantive difference in weight per-gallon between the products, as it takes a lot less Beet Juice to do the same job.

One of the biggest advantages of the Rim Guard’s product however is in terms of safety, as it’s ranked most safe among all the competitors. Calcium chloride is both corrosive and toxic even at lower doses, with windshield washer fluid rated toxic, and methanol highly flammable. Another big plus is in the temperature rating, with the Beet Juice Tire Ballast rating a -35 degrees Fahrenheit, water at +32 degrees Fahrenheit, calcium chloride about -35 degrees Fahrenheit, windshield washer fluid -25 degrees Fahrenheit, and methanol simply flammable. As you can see, Beet Juice Tire Ballast performs well in the extreme cold.

The Beet Juice product is both non-corrosive and non-toxic, and no tubes or mixing is required. Meanwhile, water is corrosive and simply not a realistic option where freezing temperatures are a possibility, while calcium chloride must be mixed on-site and can destroy rims and valve stems if leaked from the tube. Highly toxic, calcium chloride can burn skin and contaminate soil. Windshield wiper fluid is not only toxic to animals if spilled, but tubes are required for safety. Likewise, methanol must be mixed with water and weighs so much less per gallon that the Beet Juice the price could wind up being higher down the road.

The other alternative to ballasting is weight plates, which come at a cost of between $1 and $2 per pound. The struggle with using weights it that they place too much a strain on the axles and are prone to damage, just as any other piece of external equipment. Meanwhile, it takes a bit of strategic thinking to figure out where on the tractor’s frame to place them, and in the end, it’s just clear that liquid tire ballast takes the weight to the lowest point of gravity where it’s needed most.

Why ballast at all?

Experienced operators already know the answer, of course, but some just starting out may not fully understand the problem until they attempt plowing snow on a sheet of ice. Or, if they get stuck in a swampy mud. The fact is, tractors, combines, bulldozers, and just about any piece of commercial equipment has significantly more power than their frame weight can utilize. By adding weight to the tires or the frame, one can heighten the machine’s traction and prevent wheel slippage. This doesn’t just maximize power and efficiency, but it also prevents damage to the tires. Properly ballasting the tires can significantly increase machine efficiency both in terms of performance and time in field.

Every machine has a slightly different set of weight requirements, and before adding liquid ballast to the tires it’s wise to check the specifications and find that sweet spot between too little and too much. And with a little due diligence it may become clear, that the sweet spot in question tastes a lot like sugar beets.

Brian Boyce is an award-winning writer living on a farm in west-central Indiana. You can see more of his work at www.boycegroupinc.com. This article was published on behalf of Rim Guard.