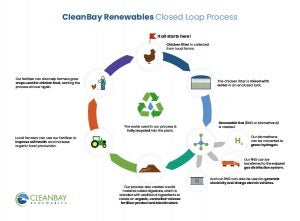

Energy company bp will be adding a new renewable natural gas (RNG) to its portfolio — all made possible by poultry litter. CleanBay Renewables — a Maryland-based company founded in 2013 that marries science, technology, and economics to agriculture for the creation of clean energy — recently entered a 15-year agreement with the fueling giant. This arrangement allows CleanBay to complete its first active facility to process poultry litter via anaerobic digestion, which will then be sold as fuel for the transportation sector, beginning in California.

“The world’s total global production of chicken litter is about 46 million tons per year,” says Donal Buckley, CleanBay Renewables CEO. “Each of our plants takes about 150,000 tons, give or take, and produces 2,100 MMBtu per day. That’s not a lot in the big gas pipeline, but in the RNG space [it is].”

Anaerobic digestion works by using bacteria to break down organic matter — such as animal manure, wastewater biosolids, and food wastes — in the absence of oxygen. The complex communities in this system produce biogas and digestate (the solid and liquid material end-products of the anaerobic digestion process) which is discharged from the digester.

According to a U.S. Department of Energy study, vehicles using RNG emit 95 percent fewer greenhouse gases compared to conventional fossil fuels.

Besides fuel, CleanBay’s anerobic digestion process also turns the remaining litter into a controlled-release fertilizer; one that the company says is more optimal for nutrient management with enhanced sustainability. By reducing pollution in the land, air and water, CleanBay is confident its anerobic digestion and RNG will create a win-win-win situation for the environment, transportation, and farmers.

Making ag shine

One of the early challenges Buckley recalls the company facing was getting the startup investments and enough capital.

“At times, we were a little envious of the wind and solar guys,” he admits, saying they tend to attract funds with ease. “The ag industry didn’t get the big investments, so we looked at that in detail and developed a plan … following a simple model where we had to get feedstock contracts that were long term.”

That saving feedstock was poultry litter.

And considering there are about 9 million broilers alone raised in the U.S. each year, which generate 14 million tons of litter, sourcing wasn’t an issue. And, it was a huge opportunity to make animal agriculture shine as an energy hero as opposed to the problem child the mainstream makes it out to be.

“In the media, it’s always ag’s fault. The whole climate change crisis is ag’s fault,” says Buckley. “In actuality, it’s not. We want to make sure that ag can continue to produce the food that people in the world want.”

He believes that anerobic digestion not only helps alleviate manure management challenges such as runoff and overwhelming storage, but it also has serious potential to entirely transform the transportation and energy sectors.

What’s so special about poultry litter?

Poultry litter stands unique among animal agriculture manures. Buckley points out that pig and cattle manures only have about 7 percent solid material compared with poultry litter, which is 70 percent.

“What makes it interesting is that as you deal with it, you’ve got a lot more nutrients and a lot more organic matter which makes more biogas,” he explains. “Then you can produce more biogas with less transportation … and produce larger volumes as a result.”

Another strength is that chickens around the world have nearly identical diets, making the RNG derived from the litter very uniform.

Future application

In the future, Buckley is optimistic that CleanBay’s method could convert litter to make “green hydrogen” — or hydrogen fuel made with renewable energy as opposed to traditional fossil fuels. He says that this, with RNG, could be a major solution to drastically cut back on the carbon footprint of the fertilizer and transportation industries.

“This is really the gateway solution,” says Buckley, enthusiastically.

Besides California, CleanBay also has sites being developed in Virginia, Maryland, and Delaware. The company is also working on a pipeline, and its R&D team is working on using fertilizer with biostimulants and other products to enhance carbon sequestration in soils.

Buckley says he and his team are very excited with the ongoing process, saying that agriculture will be a great aid to not only renewable energy, but also for reducing and capturing carbon.

“How we evolve and do that,” he said, “will make a phenomenal difference to reducing the CO2 content in the atmosphere.”

Jaclyn Krymowski is a graduate of The Ohio State University with a major in animal industries and minor in agriculture communications. She is an enthusiastic “agvocate,” professional freelance writer, and blogs at the-herdbook.com.